With 100 years of experience in designing and manufacturing Hydraulic Pressing Machines, Locatelli Meccanica has established a worldwide reputation for reliability and good quality.

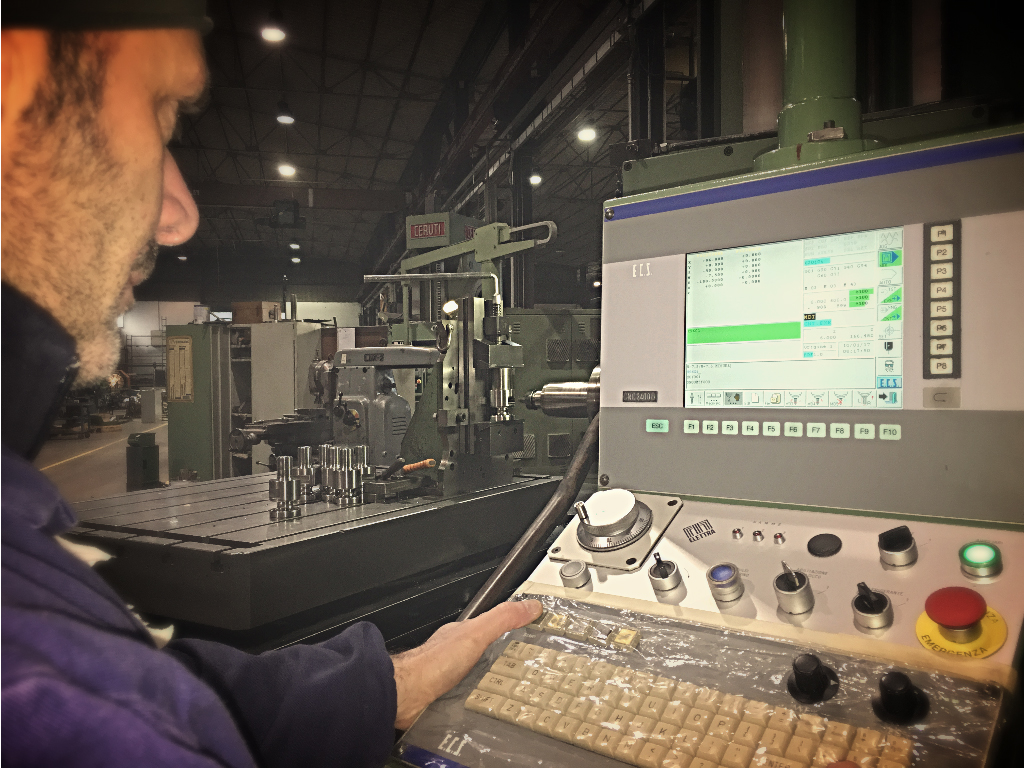

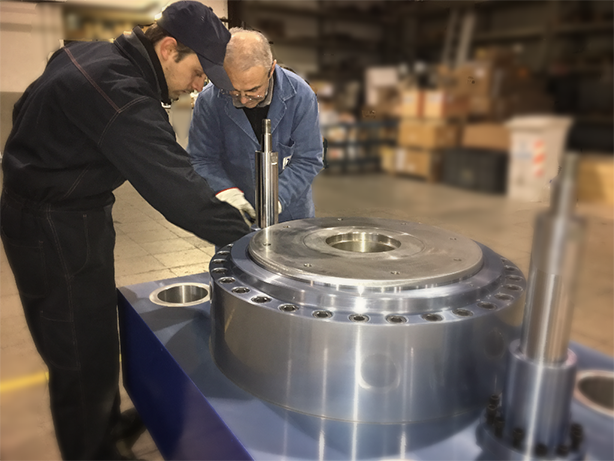

Our production ranges from Hydraulic Coining Presses to Dry Ice Machines; since all these machineries involve a Hydraulic Pressing System. Our professional staff monitors and controls all the manufacturing phases, from the design to the production, from the testing to the after-sales service, assuring product quality and professional assistance.

Through a strong worldwide agencies network, Locatelli Meccanica provides prompt feedback and strong technical support to all its clients.